revolutionizing the Cargo industry by automating container cleaning, for a safer and smarter future.

200 Million Containers are cleaned manually every year.

Each year, nearly 200 million shipping containers undergo manual cleaning — a process that is not only time-consuming and physically demanding but also dangerous. As global trade expands, so does the need for container cleaning. But this often means sending workers into tight, enclosed spaces filled with strong chemical fumes.

The result? A serious threat to worker health — from chemical exposure to chronic respiratory problems. In an industry built on movement and efficiency, this outdated method is putting people at risk.

MODULAR

ROBOTIC

PLATFORM

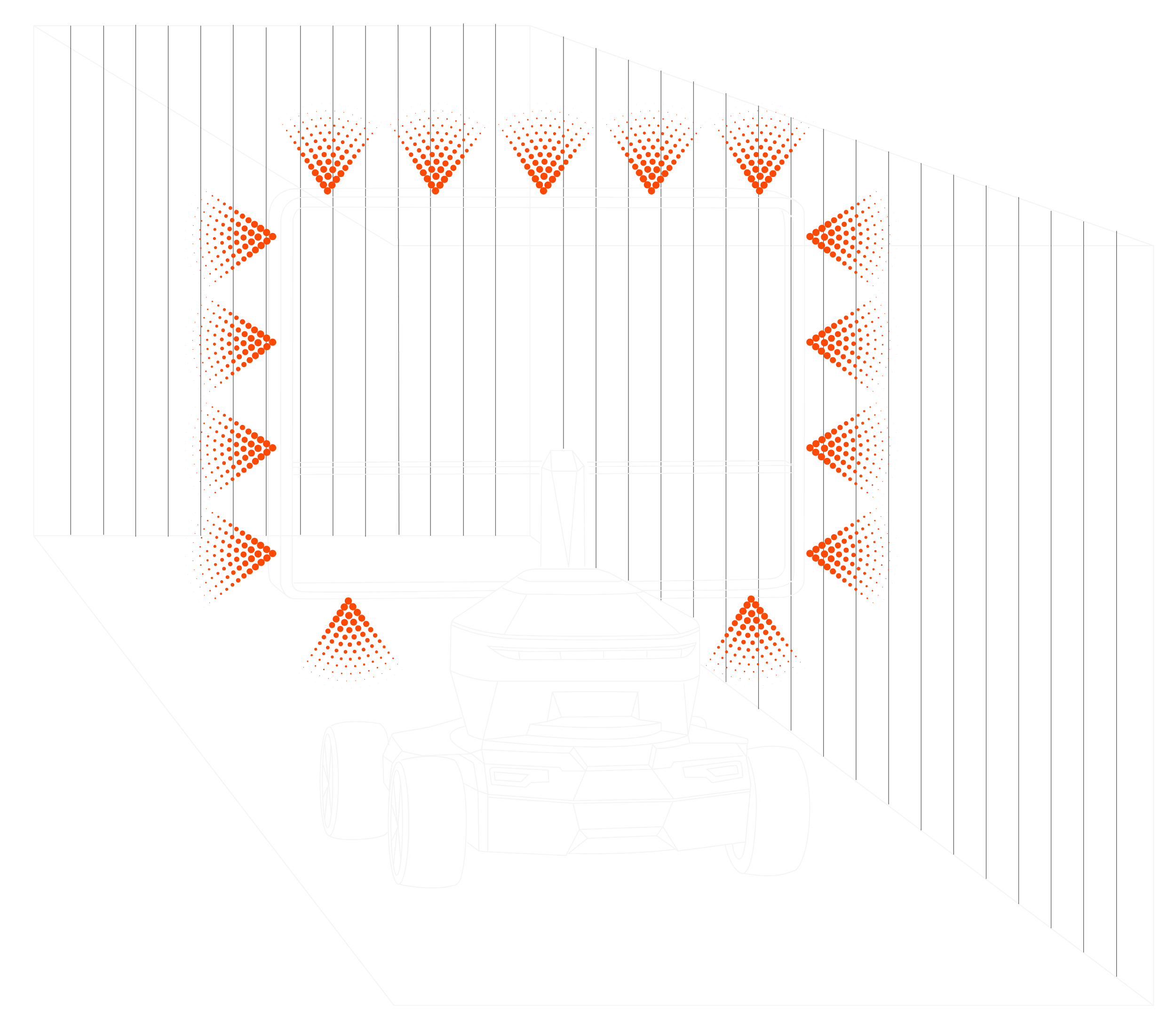

Our autonomous robotic platform is designed to adapt to different cleaning methods and port environments. Whether deployed as a robotic arm or mounted in a frame, all systems share the same underlying robotics, control software, and navigation capabilities.

• Operates inside standard ISO containers

• Fully autonomous navigation & cleaning

• Minimal setup and operator involvement

• Compatible with both dry ice and steam cleaning modules

• Easily integrated into existing port operations

OUR SOLUTIONS

Our robotic dry ice cleaning system removes contaminants without water, chemicals, or residue — perfect for eco-conscious ports and sites with limited drainage.

• No water use or drying time

• Minimizes cross-contamination (E. coli, salmonella, listeria)

• Gentle on sensitive cargo

• Low environmental impact

DRY-ICE

The steam frame system uses a robotic frame to deliver saturated steam to all container surfaces — ideal for high-volume, eco-conscious ports.

• Fast container cleaning

• Minimal water, no chemicals

• Lower operating costs

• Works in all port environments

STEAM

WATER

The high-pressure waterframe automates container cleaning with minimal water and no chemicals — ideal for high-volume, eco-friendly ports.

• Fast, efficient cleaning

• Low setup and operating costs

• Scalable for high throughput

• Operates in all port environments

Robotic cleaning is transforming container maintenance.

MCS technology replaces manual container cleaning with an automated solution that’s faster, safer, and far more efficient. It drastically reduces water and chemical use, cuts labor costs, and delivers consistent, high-quality results — every time.

But it’s about more than just performance. By eliminating exposure to harmful solvents and confined spaces, MCS also protects dock workers and promotes a healthier, more sustainable workplace.

MAXIMUM EFFICIENCY

Reduces drying time by 99% and eliminates the need for water, chemicals, and external cleaning labor.

COST SAVINGS

Delivers significant savings with a payback time of less than a year, depending on operational patterns.

MINIMAL STAFFING

Requires only 0.5 staff members per system and replaces other cleaning equipment.

ENVIRONMENTAL IMPACT

Reduces/eliminates the water consumption related to container cleaning.

Combining robotics and AI to create market leading standards

MCS Robotics uses AI vision to optimize container cleaning and inspection, delivering faster, more accurate results than manual methods. Rapid AI training enables superior defect detection, classification, OCR, and presence checks. The system integrates with industrial cameras and supports PLC communication via TCP/IP and Modbus.

SEAMLESS

INEGRATION

– IN ANY PORT

IN THE WORLD

Our robotic cleaning systems are built to slot into your existing logistics — with minimal setup, no disruption to flow, and no infrastructure overhaul.

• Operates inside standard ISO containers (20’ and 40’)

• Deployable as a fixed station, mobile unit, or portable system

• No container prep or modification required

• Onboarding, operator, and maintenance provided by us

• Remote monitoring with simple user interface

technology for

a better future

Water scarcity threatens societal stability and individual health. Addressing these challenges demands innovative solutions that support global water conservation efforts. By integrating technologies like MCS Robotics into broader climate strategies, we can strengthen infrastructure resilience, secure critical resources, and boost communities’ ability to adapt during environmental crises.

Using MCS supports SDG 8 for Decent Work and Economic Growth by promoting safer work conditions while increasing efficiency.

MCS cleans with dry ice, cutting water and solvent use, boosting safety, saving resources, and reducing environmental impact — supporting sustainable industry and infrastructure.

MCS uses dry ice, an industrial by-product, instead of water for container cleaning — eliminating the need for water heating and enabling a carbon-neutral process.

Our technology prevents chemical runoff, supporting SDG 14 by protecting marine biodiversity and promoting sustainable use of ocean resources.

MCS supports the UN’s SDG 6 for Clean Water and Sanitation by reducing wastewater and mitigating the environmental

impact of the cleaning process.